Unplanned downtime.

Untapped pay zones.

Stuck pipe. It all adds up.

Unplanned downtime.

Untapped pay zones.

Stuck pipe. It all adds up.

From wellhead to refinery

- + UPSTREAM OPTIMIZATION

- + MIDSTREAM OPERATIONS

- + DOWNSTREAM ECONOMICS

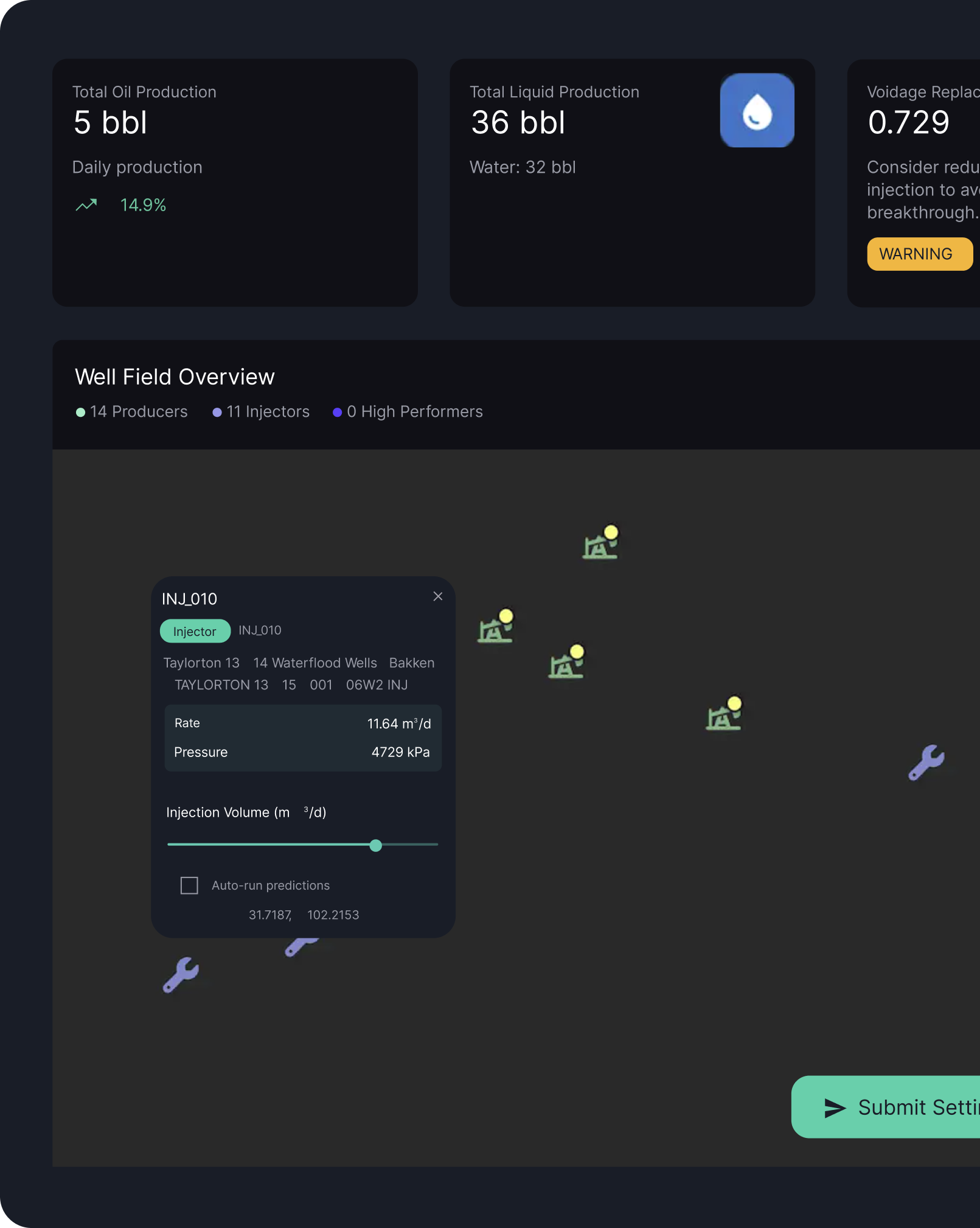

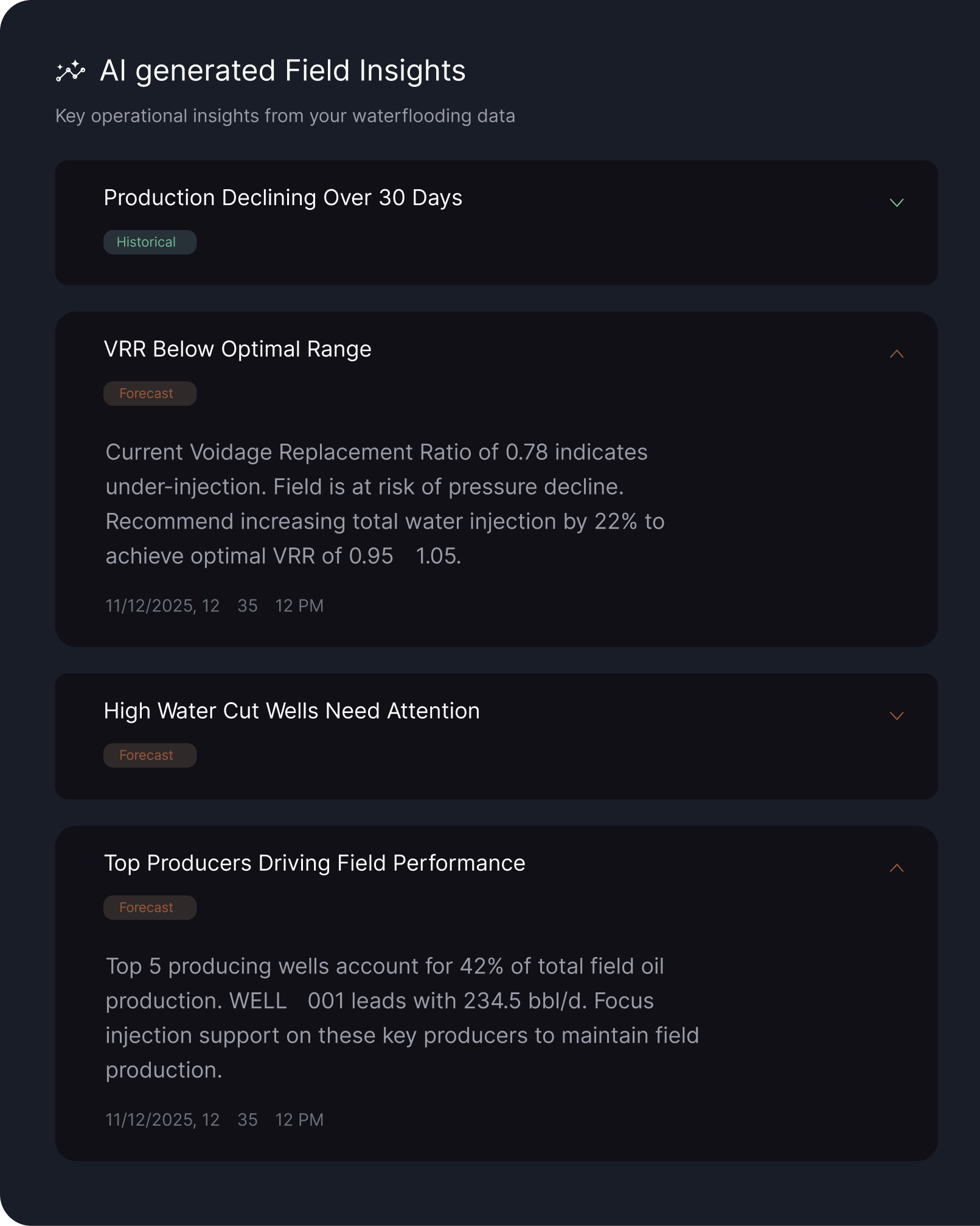

Optimize upstream operations

Asset failures, drilling delays, and underperforming wells can escalate into multimillion-dollar losses when they go unseen or unresolved. With agentic AI, operators can:

- Monitor wells, facilities, and pipelines in real time to surface emerging issues before production is impacted

- Detect equipment degradation and stuck-pipe risk days or weeks before unplanned downtime

- Adjust drilling parameters and trigger targeted field interventions early to protect recovery and asset utilization

Protect throughput and pipeline integrity

Midstream assets are remote and exposed. Manual monitoring and reactive maintenance can’t keep pace with distributed pipeline networks — where small issues quickly become safety and reliability risks. With agentic AI, operators can:

- Predict component failures weeks in advance to support preventive repair scheduling

- Optimize pigging and inspection schedules dynamically based on asset condition

- Detect network anomalies in real time to trigger rapid safety intervention

- Forecast crew demand and optimize inventory to keep maintenance operations moving

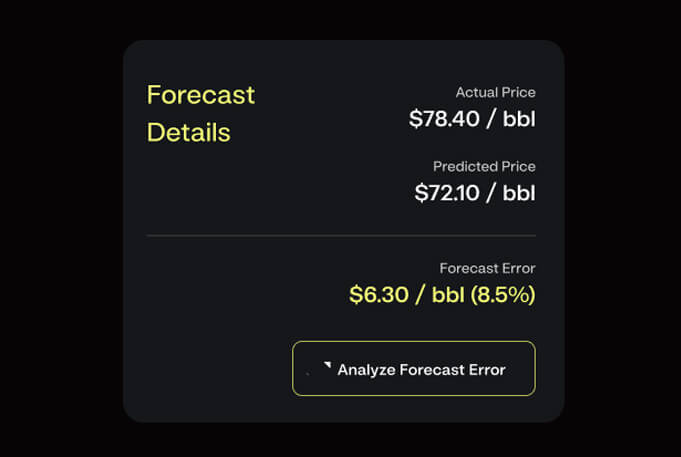

Maximize refining margins and ensure ESG compliance

Refinery margins swing with market volatility. Small process inefficiencies cost millions, while static control systems struggle to keep up with shifting crude slates, product demand, and constant ESG pressure. With agentic AI, operators can:

- Execute real-time process control to maximize yield across critical refining units

- Optimize crude blending using price forecasts and target product slates

- Predict and prevent flaring events to reduce waste and compliance risk

- Forecast commercial demand and dynamically adjust the production mix

From wellhead to refinery

Why oil and gas operators choose DataRobot

-

Governance and data security built in from day one

In high-stakes operations, governance isn’t optional. DataRobot enforces audit trails, lineage tracking, and approval workflows from the moment you build an agent. Every autonomous decision is fully auditable, showing what triggered it, what data informed it, and who approved it.

-

Deployment that works anywhere operations run

Operations don’t stop when connectivity drops — and neither should your AI. With DataRobot, teams build, deploy, and govern agents that run at the edge with NVIDIA-powered performance, keeping intelligence close to the equipment when connectivity is limited or air-gapped.

-

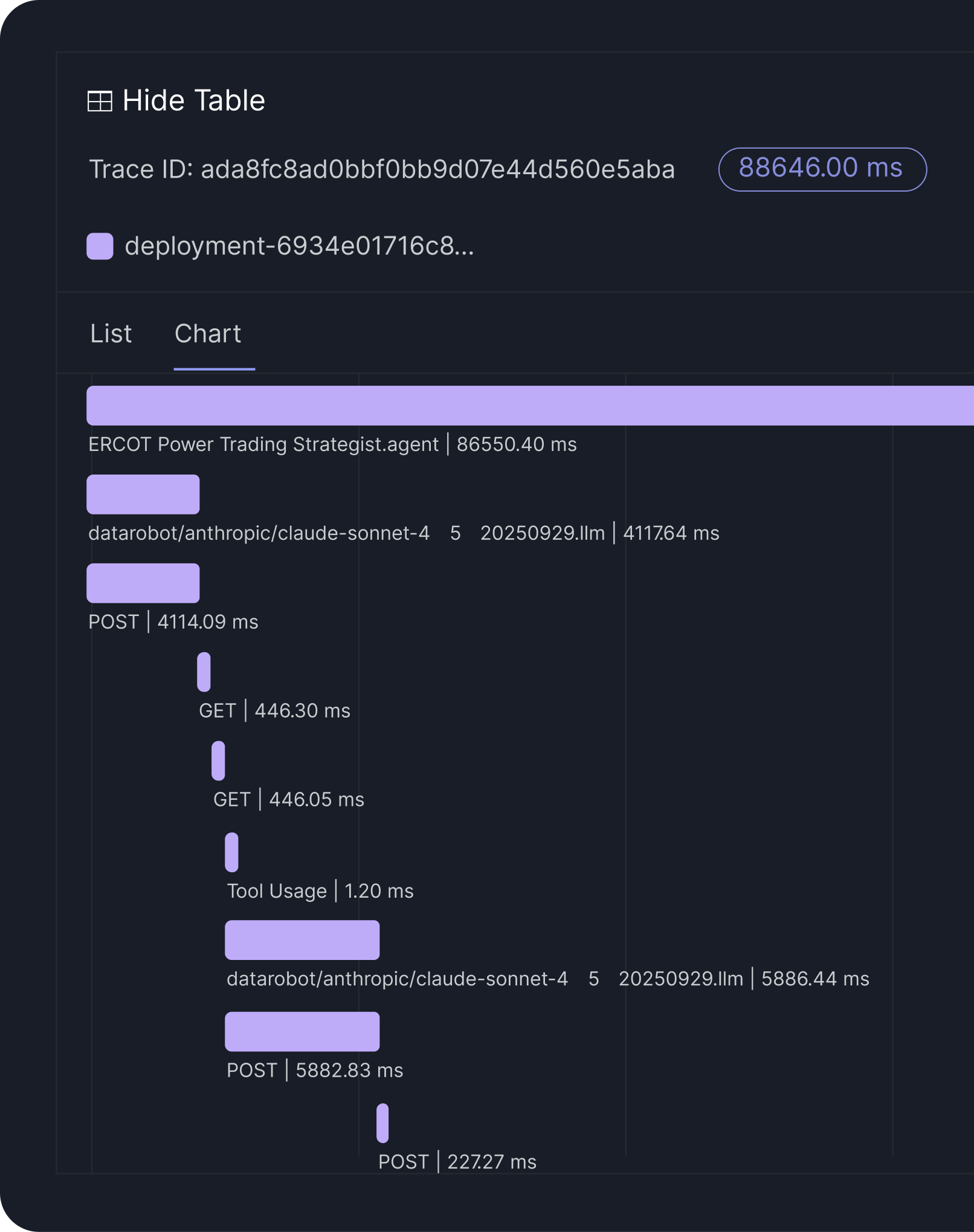

Agent-led orchestration that bridges warning signs to corrective action

Insights only matter when they turn into action in the field. DataRobot integrates directly with operational systems, historical databases, SCADA controls, CMMS platforms, so agents can move from analysis to action.

Why oil and gas operators choose DataRobot

Governance and data security built in from day one

In high-stakes operations, governance isn’t optional. DataRobot enforces audit trails, lineage tracking, and approval workflows from the moment you build an agent. Every autonomous decision is fully auditable, showing what triggered it, what data informed it, and who approved it.

Deployment that works anywhere operations run

Operations don’t stop when connectivity drops — and neither should your AI. With DataRobot, teams build, deploy, and govern agents that run at the edge with NVIDIA-powered performance, keeping intelligence close to the equipment when connectivity is limited or air-gapped.

Agent-led orchestration that bridges warning signs to corrective action

Insights only matter when they turn into action in the field. DataRobot integrates directly with operational systems, historical databases, SCADA controls, CMMS platforms, so agents can move from analysis to action.

Trusted by the world’s leading energy enterprises

Leader in Gartner Magic Quadrant for Data Science and Machine Learning Platforms

DataRobot meets the industry’s most demanding InfoSec, sustainability, and operational standards — ensuring every agent and application operates with full visibility, lineage, and control. Our Agent Workforce Platform keeps real-time decisions reliable, auditable, and compliant from field to enterprise.

- SOC 2 Type II

- ISO 27001

- GDPR

- NIST AI RMF

- Flaring Reduction

- Emissions Optimization

Resources for Oil and Gas